Polyester Printing .....you know you have to read this.

I would love to meet the guy who invented polyester and have a few stern words with him in a dark quiet room.

I am not a scientist; I am a printer! On a sliding scale printer is nowhere near scientist in fact it slides in the direction of Warlock and Charlatan.

I don’t know the origins of Polyester all I know is that its not organic, it’s not found naturally, that doesn’t make it bad or evil or even belonging to the underworld! It means that at some point a few people cleverer than I decided it was less work to take a bi-product of the petrochemical industry and make a running vest out of it than grow cotton pick it and spin it.

Polyester makes up more than half of the clothing manufactured now (don’t quote me, I'm sure I read it online so it could be true who knows?) so as printers we must get accustomed to printing on it.

I did a little research on this topic and it didn’t really reveal any huge secrets. This is mainly because there are none!

Polyester is made of super long fibers its made in lots of different ways and different manufacturers use different methods and shapes of fibers, some round some triangular some are multifaceted but as I mentioned before, I am not scientist, the fibers are uniform and smooth which actually makes them really good for printing onto, we all hate the little fluffy fibers that stick up through our pristine prints and make them look as fluffy as a freshly brushed spaniels ears.

So why is polyester printing the thing that strikes fear into printers more than when a friend says “oh you print shirts? Can you print some for me?” (I now tell people I am a gardener, because I would rather dig someone’s garden than print shirts for a friend! It always ends in disaster).

The answer is simple: HEAT MANAGEMENT!

Normal printing inks are either solvent based or water based, solvent inks require a specific temperature to link onto the fibres of the shirt usually 160c, Polyester is hydrophobic (I sound like a scientist now) basically it is plastic and doesn’t accept water without chemical additives. We will concentrate on solvent based inks.

The polyester is a great fabric that can withstand lots of laundry cycles at a full range of laundry temperatures, however the disperse dye that is used on most polyester fibers starts to get seriously annoyed with high temperatures, this is what makes printing on polyester such a challenge. We need to heat the ink film that we have sold our souls to make look so pristine and aligned perfectly, to a high enough temperature to ensure the shirt doesn’t end up on a facebook page titled “ Don’t buy from this guy his prints are temporary”. But at the same time, we have to try not to annoy the polyester which is like a teenager without WIFI, it looks ok now but it could blow at any moment.

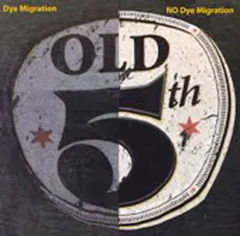

The way I try to describe polyester printing is to imagine the ink layer we just applied is like a million tiny straws laid on top of the shirt facing upward, when we apply heat to this mixture, the polyester dye starts to run up the straws like marker pen ink up chromatography paper (or like the guy at the end of the dryer running to get his coat on as soon as the press goes into outlet mode.)

The secret is to stop the dye before it reaches the top of the straws. If it stops halfway up, the divine white we just took hours to place perfectly on the “Codfather fish and chip shop” sponsored navy running vests doesn’t turn a delightful shade of ice blue right before our eyes.

There are many products on the market that claim to be suitable for 100% polyester and I am sure they are, they have probably been tested in the best labs in the world by all the guys that did so much better than me at school and became scientists rather than practicing the dark art of squeegee pulling (don’t be a pusher it’s just wrong), but my advice would be find the one that works for you, Grey blocker base is fantastic for slowing down the rampant march of the ever so eager to be seen dyes as it contains chemicals that basically stick a foot out near the door and trip up the running catcher before he can clock out, but it can change the shades of colors printed on top, this means using an extra screen for white base which also means extra heat to gel it, the endless cycle continues.

My advice is to lower the required temperature needed to get the ink to stick to the substrate ( scientists word for vest), this can be done with either a ready to use ink that cures at or around the 140c mark, there are plenty on the market now or add a catalyst to the ink to allow it to cure at really low temps, but this will shorten the shelf life of the ink to hours instead of years! Its important to note that the dryer should be reliable, if it says 140c on the display it’s important that it doesn’t really reach 160c inside the dryer, use a Donut type thermoprobe, this will accurately tell you where the ink film temperature is and not the ambient temp in the oven.

The heat management doesn’t stop at the flash and the dryer, flash times need to be low to avoid shrinking and to not kick start the catcher’s dash to the door, at the end of the dryer the “Codfather” vests need to be stacked in very small piles, I have found that if you have the table room then make ten stacks and place a vest on each pile in succession, the heat is dispersed quickly, we have all come in to the print shop on a cold morning and felt the heat still locked into that huge stack of shirts that were printed the previous day, the heat locked into the shirts is basically the fuel for the dye to keep running up the straws. Kill the heat as quickly as possible, use a fan, hook up an airline, put the table on wheels and run it round the car park! Whatever it takes. Just get the vests up to temp to cure the ink, and then cool them down as quickly as possible, I have seen a chest freezer in one print shop that was used to cool down wayward prints.

In summary the advice is simple, Control the heat and you control the bleedin’ polyester. There are tools out there to help you, so use them. Keep the temperature under control and you will be happier than the teenager when the WIFi returns to full strength. A mixture of dye blockers, low cure additives and finely tuned drying equipment will ensure you don’t walk in the following day after a successful print run, open the box and utter those immortal words “are these Codfather vests supposed to be light blue?”

Article written by Tony Palmer, Palmprint

Tony has more than 30 years experience in garment decoration ranging from manual screen printing on hand carousels to the operation of multi-color automatic presses. Specifically Tony is an expert on MHM Automatics, Tesoma, Exile Spyder, Douthitt CTS, Zentner, and numerous manufacturers of textile decorating equipment.